Albert Einstein said that “in the midst of every crisis lies great opportunity.” There is no better example than Alberta start-up company Westgen Technologies, which is gaining international attention for helping to eliminate a significant source of greenhouse gas emissions.

Westgen’s co-founder Ben Klepacki was working as a facilities engineer for a major natural gas producer in Western Canada three years ago when a fire occurred at one of the company’s remote well sites, injuring an employee. The incident was caused by a build-up of gas in a separator building, which was sparked when the maintenance worker entered the building. The company tasked Klepacki with finding a way to stop the small but frequent releases of natural gas that are common on gas wells around the world, as pressure from the well is used to move valves and other pneumatic devices, resulting in a puff of gas escaping each time the equipment is activated. The solution he developed was a small air compressor run off a hybrid natural gas/solar generator that provided just enough electricity provides enough air to operate the pneumatics and power to run the site, while eliminating the release of natural gas.

By fixing a safety hazard, Klepacki also addressed a pressing environmental problem. As the main component of natural gas, methane is also a potent greenhouse gas that is 25 times more powerful than carbon dioxide. And with Canada recently adopting some of the world’s strongest regulations to reduce methane emissions, the Canadian energy sector is seen as a frontrunner in managing the issue thanks to its proactive approach to limiting emissions over the last decade.

“Methane is a great case study for how Canada is a leader when it comes to responsible energy development,” says Klepacki. “In our case, we knew that the rules around methane emissions were just going to get tighter, so we focused on solutions that are cost-effective and provide an incentive for companies beyond just meeting the regulations because they improve safety, reduce emissions and save natural gas that can be sold to their customers.”

Klepacki teamed up with his friend Connor O’Shea to further develop the technology as a business venture, resulting in the launch of Westgen last fall. They have already inked deals with several small and large Canadian gas producers, they are getting calls from potential customers in the United States and South America, and Westgen has been nominated for the Emerging Clean Technologies category of this year’s Global Energy Awards.

“Methane emissions are a really important subject right now and Canada is leading the path on emissions reductions,” says O’Shea. “Alberta’s approach of using carbon credits to incentivize early action, combined with clever financing options, have made using products like ours an attractive proposition for producers. It is the carrot rather than the stick approach, and it has resulted in significant reductions.”

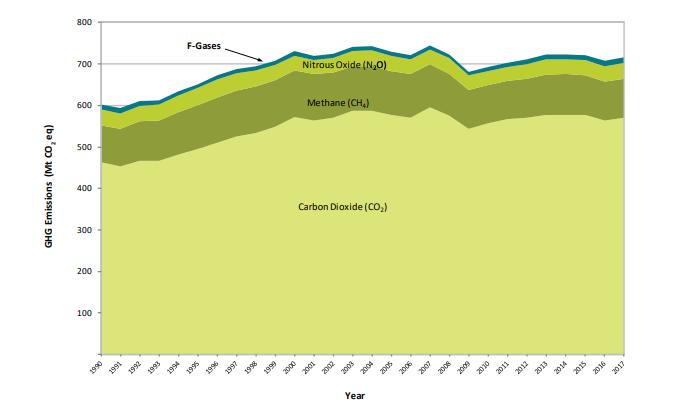

Methane emissions account for 13 per cent of Canada’s total GHG emissions, with 43 per cent coming from the oil and gas sector. The industry’s emissions decreased 14 per cent between 2005 and 2017, and new federal targets that came into effect on Jan. 1 require a 45 per cent reduction from 2012 levels by 2025.

“We have been working on the methane file for more than 10 years now, and it is clear that conserving methane pays off in the long run because you are utilizing it and not wasting it,” says Soheil Asgarpour, president of the Petroleum Technology Alliance Canada (PTAC), which co-ordinates research and development work on behalf of industry, government and academia. PTAC has invested $5.75 million in projects to improve leak detection and mitigation that have eliminated more than 820,000 tonnes of CO2-equivalent GHG emissions per year– equal to taking 164,000 cars off the road. Through technology and best practices, PTAC estimates the industry stands to save an estimated $550 million per year by achieving the 45 per cent reduction.

“Most of the technological capacity is already in place, our focus now is on doing what we can to fast-track the uptake and implementation across the industry at a time when the producers are facing significant challenges,” Asgarpour says.

From the international majors to small independent operators, Canadian energy companies invest more in environmental protection than any other industry. They have a long track record of innovation and making significant investments in minimizing methane emissions – most of which occur during the production and transportation of natural gas.

Shell Canada has reduced GHG emissions by 91 per cent at its gas wells built in northeastern B.C. since 2018 by using electric-powered valves. The company is aiming to replace equipment at many of the older sites in its 500-well Groundbirch project as well, even though the facilities already exceed Shell’s global methane emissions targets.

Pipeline giant TC Energy has been investing in research and development to reduce methane loss from its facilities for decades, and is sought out by peers around the world to learn from their expertise. The company, which transports most of the natural gas produced in Western Canada to markets across North America, holds patents to numerous devices that minimize or eliminate methane leaks from valves and seals and pioneered the use of hand-held leak detection devices as part of its inspection practices. It also invented a fleet of mobile compressor stations that capture large volumes of gas that are traditionally released into the atmosphere during pipeline maintenance work – saving an estimated one million tonnes of GHG emissions per year, equivalent to taking 225,000 cars off the road.

Many mid-sized gas producers are constantly striving to stay ahead of environmental regulations as well, explaining that using best practices for reducing greenhouse gas emissions pays off in the long run in terms of cost savings, as well as the reputational benefits of being known as leaders in sustainable energy development.

“We don’t wait to be told what is acceptable. We know that the eyes of the world are on us and we are constantly improving because it’s the right thing to do for our shareholders as well as the broader community,” says Jeff Tonken, the CEO of Birchcliff Energy, which produces natural gas and light oil in the Peace River Arch area of northwestern Alberta. Birchcliff’s GHG intensity has steadily declined over the last three years, as the company employs solar panels, micro wind turbines and other forms of electric generation to avoid gas-driven pneumatics at most of its sites, and also uses vapour recovery devices to capture vented methane and return it to the system.

Similarly, Seven Generations Energy (7G) has the lowest GHG emissions intensity in its peer group, thanks to ongoing efforts to install and retrofit its facilities with the latest technology. In advance of the current methane regulations coming into effect, 7G conducted a sweeping leak detection and methane emissions reduction program, reducing emissions by more than 19,000 tonnes of CO2-equivalent per year. The company’s emissions reduction efforts were a key piece in becoming the first company to be designated a ‘responsible natural gas producer’ by New York-based Equitable Origin. The certification enables 7G to supply gas at a premium price to Energir, Quebec’s largest gas provider, through a supply contract announced earlier this year.

Even some of the smallest oil and gas companies are leaders in emissions reduction, proving that size doesn’t matter when it comes to being committed to sustainability. Calgary-based Modern Resources beat out Saudi Aramco for the Global Petroleum Show’s environmental excellence award in 2018. The win was largely due to the company’s drive to eliminate methane emissions from its well sites in northwest Alberta through smart engineering and use of the latest technology such as solar powered valves and vapour recovery units at its remote sites.

“We have taken our methane emissions to zero, but we say that our facilities are ultra-low emissions because they still emit a small amount of CO2 – less than a newborn baby,” says CEO Chris Slubicki, adding that his company has already met the new methane regulations. “Some like to say that the oil and gas industry is against solutions, but that’s not the case at all. We are all for solutions because they are generally win-win and make us money.”

With global demand for oil and gas dropping significantly due to the COVID-19 pandemic, Westgen Technologies is expecting some of its growth plans may take longer than expected. But they are hopeful that the federal government’s $750 million loan program for methane emissions reduction projects in the energy sector will yield new opportunities.

“It could have a big impact on our industry,” says O’Shea, adding that all of his company’s equipment is manufactured in the Calgary area with technology and supplies from across Canada. “It would accelerate employment across the supply chain and help our industry become even more of a leader on the international stage.”