Canada’s oil and gas industry is recognized as having a level of cooperation on cleantech research and development that is unprecedented globally. Today that cooperation is resulting in a flood of new cleantech development projects.

Here are a few emerging partnerships in cleantech initiatives to watch:

Turquoise Hydrogen

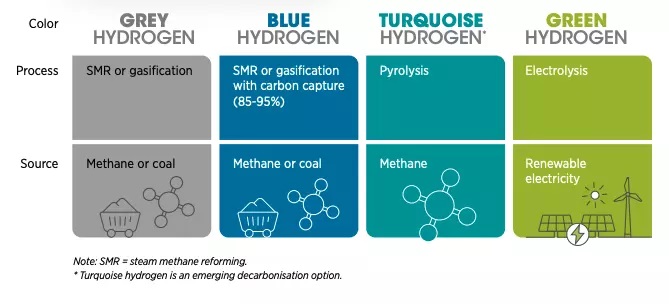

If you’re starting to get lost in all the colours of hydrogen – grey, blue, green – there are multiple pathways for hydrogen production. Each pathway is differentiated by the colour spectrum from black to yellow; however, most have not been commercialized.

Hydrogen can be generated from biomass (yellow), water (green, pink), and fossil fuels (black, brown, grey, blue, turquoise). The colour designation relates to the cleanliness of the power source used in generation, the associated emissions, and whether or not they are captured.

Source: International Renewable Energy Agency

Baker Hughes has announced an investment in Vancouver-based Ekona Power Inc. to advance development of a unique low-cost methane pyrolysis technology platform to produce cleaner turquoise hydrogen.

Compared to traditional steam methane reforming processes used to produce industrial scale hydrogen, Ekona’s process can produce hydrogen at costs on par with current systems while reducing emissions by more than 90 per cent.

The technology will be applicable to many markets including upgraders, refineries, chemical plants, and natural gas transmission and distribution companies looking to reduce their GHG emissions footprint.

Decarbonizing existing assets

TC Energy and Irving Oil announced they will work together to lower emissions by decarbonizing existing oil and gas operations and deploying new technologies.

The partnership’s initial focus will consider a series of upgrades at Irving Oil’s refinery in Saint John, New Brunswick, with the goal of significantly reducing emissions through the production and use of low-carbon power generation.

Other opportunities such as the production and distribution of low emission hydrogen and establishing a world class carbon capture and sequestration network will aid in decarbonizing local industries and position Atlantic Canada for development and job opportunities well into the energy transition.

TC Energy and Irving Oil have a history of working together, including the development and operation of the Grandview Cogeneration plant, reducing the carbon intensity of the top-tier Saint John refinery resulting in up to 750,000 tonnes of avoided GHG emissions – the equivalent of taking over 160,000 vehicles off the road.

Solar farm to power refinery

Shell Canada has announced plans to build a 58-megawatt solar farm adjacent to the company’s Scotford refinery and chemicals park near Edmonton.

Shell subsidiary Silicon Ranch will build and operate the solar farm which is expected to produce enough renewable electricity to provide 20 per cent of the refinery’s energy needs for at least the next 25 years.

While most solar farms are typically built in the southernmost portion of the province, this project will mark the first large-scale solar installation in Alberta’s industrial heartland and be designed with panels that can capture sunlight reflected off snow.

Silicon Ranch and Shell will construct a solar farm to help power the Scotford refinery. Photo courtesy Shell Canada

Emissions reduction and economic recovery

Canadian companies Suncor Energy and ATCO Ltd. are collaborating on a potential hydrogen project near Edmonton that would produce more than 300,000 tonnes per year of clean hydrogen using advanced technology to capture more than 90 per cent of the emissions generated in the production process.

Suncor and ATCO have established projects throughout the province that support thousands of jobs and hundreds of communities. This encourages investment along the hydrogen value chain; from production, to carbon capture and storage, and end-uses such as hydrogen fuel cell trucking.

Eighty-five per cent of the produced clean hydrogen would be used to supply existing energy demand, with 65 per cent of the output used in refining processes and cogeneration of steam electricity at the Suncor Edmonton Refinery, reducing refinery emissions by 60 per cent.

In addition to supply clean hydrogen to Suncor and the Alberta gas grid, the project would make hydrogen volumes available for other industrial, municipal, and commercial transport users.

The hydrogen production facility would be located at ATCO’s Heartland Energy Center and could be operational as early as 2028, reducing carbon dioxide emissions in Alberta by more than two million tonnes per year.

Polaris Carbon Capture and Storage

Indigenous leaders have reached a deal to work with Shell Canada on the company’s proposed Polaris carbon capture and storage project northeast of Edmonton. First Nations partners are working to raise funds for a potential agreement to acquire an equity position in the storage hub.

Polaris will be the second CCS project at Scotford. The first, Quest, started operating in 2015 and has so far safely sequestered more than six million tonnes of CO2.

The project will create 2,000 jobs and have the capacity to capture and store up to 750,000 tonnes of carbon per year from the Shell-owned Scotford refinery and chemicals plant, the equivalent of removing over 160,000 vehicles from the road each year. If approved, operations would start in the mid-2020s.

The unaltered reproduction of this content is free of charge with attribution to Canadian Energy Centre Ltd.